Permeable paving guidance

Permeable block paving will not be considered as a suitable surfacing where it can be subject to accidental fuel and oil spills. This includes, but is not limited to, petrol forecourts and bus stops.

In general, porous asphalt proposals shall be limited to areas in the borough that are subject to Traffic Categories 1 to 4, as defined in BS 7533. The use of permeable block paving SuDS features under Traffic Categories 5 or higher shall be discussed with one of our representatives on a case-by-case basis.

Runoff interception

Permeable block paving solutions are considered Source Control SuDS features. As such, they capture and store rainfall landing directly on its surface. However, it can also handle additional adjacent impermeable areas of paving and roofs.

In general, it is standard practice to limit the ratio of impermeable area to permeable pavement/asphalt to 2:1, as indicated in Section 20.2 of the SuDS Manual.

Site suitability

Permeable paving is suitable for:

- Car parks

- Play areas

- Low-traffic roads, including private driveways

- Pedestrian only areas

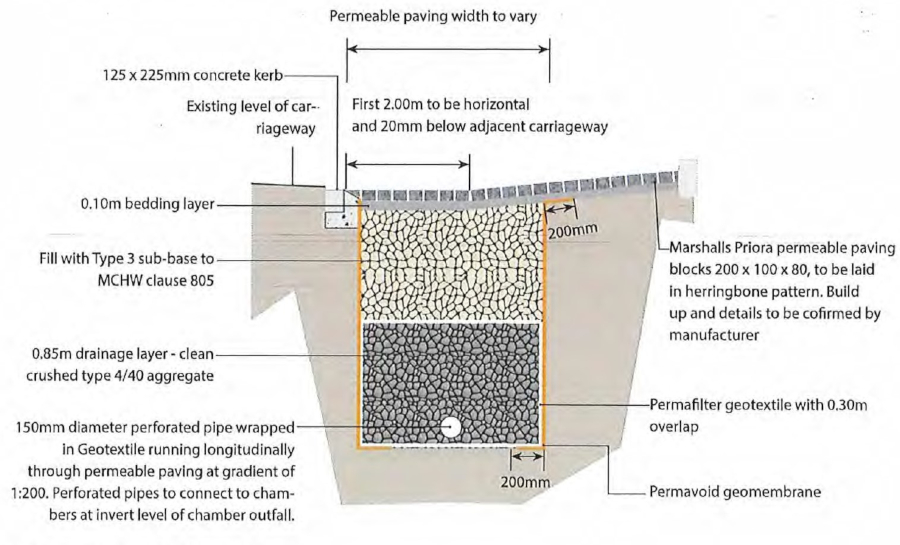

Typical permeable paving detail

The diagram shows measurement and details of typical permeable paving.

Materials

This section describes in detail the materials and recommended depths of a typical permeable block paving build up based on sites with subgrades with 5% California Bearing Ratio (CBR) or higher.

For sites with lower CBR values the designer shall provide subgrade improvements, introduce a capping layer and/or using geogrids. Further advice on this can be found in Section 20.9.6 of the SuDSManual.

Build up

Typical build up of permeable block paving shall follow the recommendations set by the specific proprietary product supplier. The values in the table are based on Marshalls' Priora permeable block paving, but the designer can use alternative suppliers if preferred.

The 'paving block' layer, as indicated in the table, shall consist of any specific proprietary product available in the UK market. Careful consideration shall be given to the jointing aggregate material as it will allow matter to easily pass though into the sub-base without clogging.

The 'bedding layer' shall consist of 6mm open graded crushed rock, with no fines, to provide maximum percolation.

The sub-base layer shall consist of Type 3 material to MCHW Clause 805, with a minimum 30% void ratio.

| Traffic category | Paving block | Bedding layer | Sub-base |

|---|---|---|---|

| 1 | 80mm | 50mm | 150mm |

| 2 | 80mm | 50mm | 200mm |

| 3 | 80mm | 50mm | 275mm |

| 4 | 80mm | 50mm | 300mm |

Provision of further storage

Further storage can be placed to increase the storage even further due to their much higher porosity - geocellular tanks, for instance.

Geotextile

The geotextile will act as a separation layer between preventing aggregate migration between sub-base components. It shall be placed directly above the subgrade and below the laying course.

The designer shall check with the permeable block paving supplier the selection of an acceptable geotextile.

Up to: Dropped kerbs

Updated: 03 December 2025

Stay up to date! Make sure you subscribe to our email updates.

Stay up to date! Make sure you subscribe to our email updates.